Lazerarc Blog

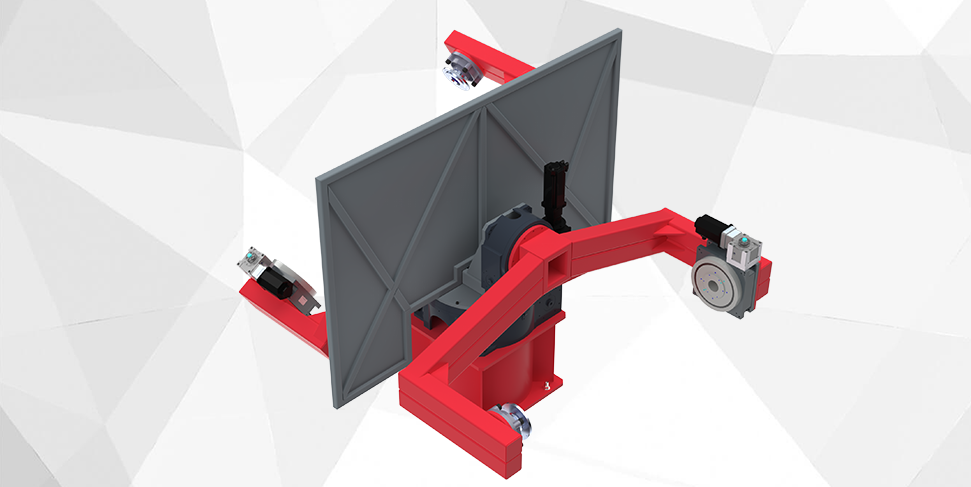

Zero Backlash 5 Axis Robotic Positioning Systems

At the forefront of robotic positioning technology, our 5-axis robotic positioning systems are engineered to deliver unparalleled precision and reliability, thanks to the integration of zero backlash cam indexers across all axes. Designed to meet the rigorous demands of modern manufacturing and automation, these positioners offer a revolutionary solution for complex positioning tasks.

Unmatched Precision and Smooth Operation

Our 5-axis positioners leverage the unique capabilities of zero backlash cam indexers to provide smooth, precise, and efficient movement. The absence of backlash — the play between mating components — is critical for high-precision tasks, ensuring that the positioner’s movement is always exact and predictable. This precision is vital in applications where even a micron’s deviation could compromise the quality of the product or the integrity of the process.

Enhanced Durability and Reliability

The zero backlash cam indexers incorporated into our positioners are not only about precision; they also significantly enhance the durability and reliability of the system. By eliminating backlash, we reduce the wear and tear on moving parts, thereby extending the lifespan of the positioner and minimizing maintenance requirements. This reliability is crucial in high-throughput production environments where downtime can be costly.

Embrace the Future of Precision Positioning

Our 5-axis robotic positioners with zero backlash cam indexers represent the pinnacle of positioning technology. By combining sophisticated engineering with high-quality components, we offer a solution that enhances both the efficiency and quality of your manufacturing processes. Whether you’re looking to upgrade your current system or integrate advanced positioning capabilities into a new project, our positioners are designed to deliver unmatched performance.

Importance of Zero to Extremely Low Backlash

Precision and Accuracy:

Backlash can lead to positioning errors, affecting the precision and accuracy of the robotic positioner. Zero to extremely low backlash ensures that the movement of the positioner directly translates to the intended motion of the workpiece, crucial for tasks requiring high accuracy such as machining, welding, and assembly.

Repeatability:

In processes where the same action is repeated multiple times, such as in mass production, minimizing backlash is essential to achieve high repeatability. Consistent performance without the variation caused by backlash ensures that each part is produced with the same specifications and quality.

Surface Finish and Quality:

For operations that impact the surface finish, like milling or painting, backlash can lead to imperfections and a lower quality finish. Reducing backlash helps in achieving smoother operations, leading to better surface quality of the finished product.

Reduced Wear and Tear:

Mechanical systems with less backlash undergo less stress and strain during operations, leading to reduced wear and tear. This prolongs the life of the equipment, decreases maintenance costs, and ensures consistent performance over time.

Faster Speeds and Higher Throughputs:

Systems with low backlash can operate at faster speeds without sacrificing accuracy. This capability allows for higher throughputs and more efficient production cycles, beneficial in high-volume manufacturing environments.

Customer Satisfaction and Competitive Advantage:

Delivering products with higher quality and consistency directly impacts customer satisfaction and can provide a competitive advantage in the market. Zero to extremely low backlash in robotic positioners can be a key factor in achieving these outcomes.

See how we can help you