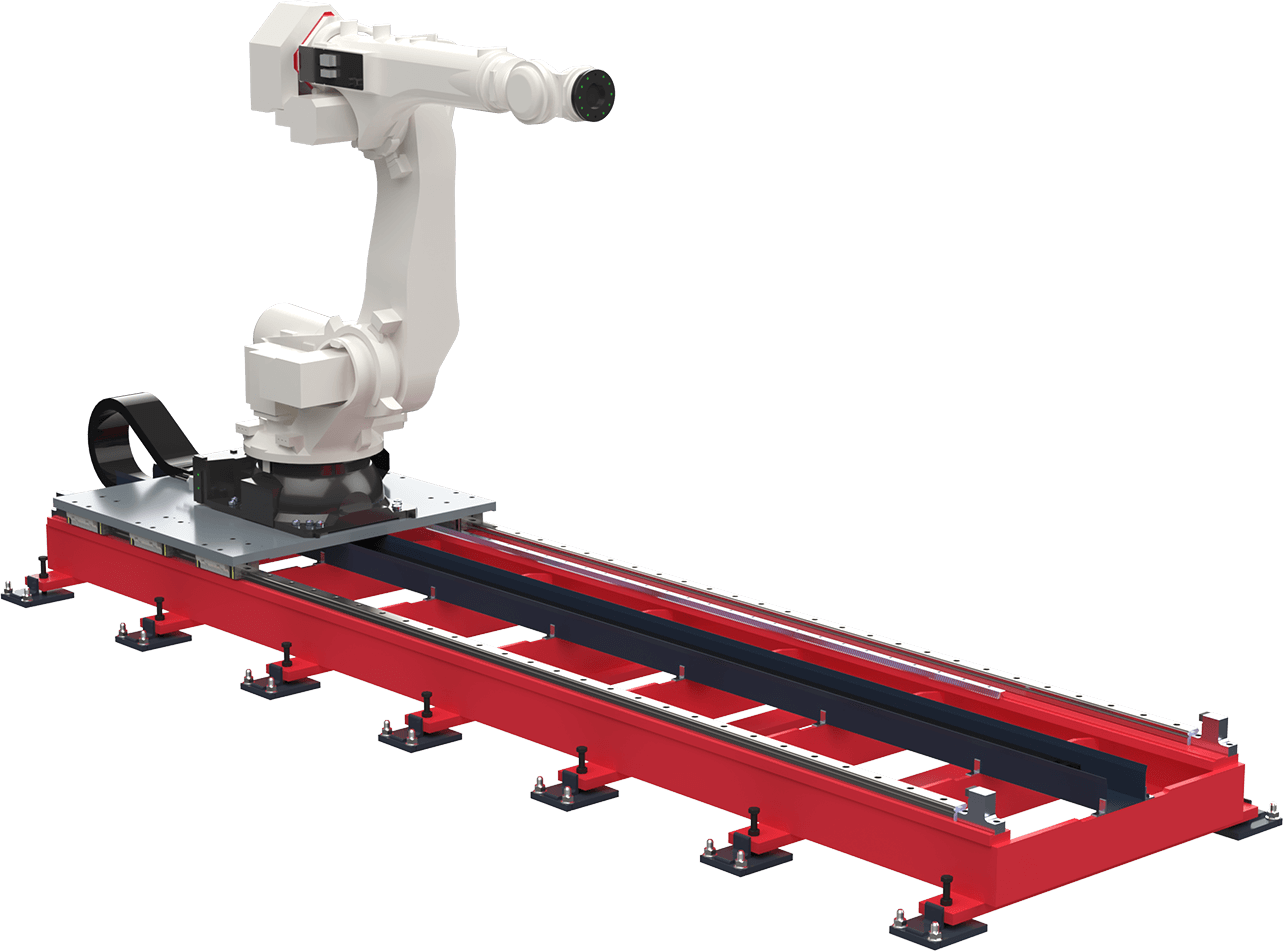

ROBOT Transfer Unit

Robot Transfer Units add a 7th axis to a robotic arm, expanding the robot’s reach along a linear track. This mobility allows the robot versatility to automate multiple steps of a production process, making it possible for manufacturers to accommodate larger parts in greater workspaces. Robot Transfer Units efficiently move parts between workstations at 1.5 meters per second without delays, creating faster cycle times.

LazerArc Robot Transfer Units can be manufactured in elevated, floor mounted or inverted configurations. They can be engineered to any length that the customer requires. Our design incorporates machined keyed ends that allows for sections to be added or removed easily for re-purposing. Each unit is equipped with adapters to fit your specific robot or servo motor.

KEY FEATURES

- Accuracy of +/- 0.003” /ft

- Pre-Machined Carriage to Secure Robot

- Oversized Linear Bearings

- Machined and Keyed Ends

- Cable Management System

OPTIONS

- Power and Communication Cables

- Bellow Guard for Linear Bearings

- Leveling Plates

- Auto Lube Systems for Gear

- Higher Accuracy

- Custom Robot Risers

APPLICATIONS

Our Robot Transfer Units are specifically designed to enhance efficiency and precision in various industrial processes, catering to sectors such as warehousing, high production machining operations and industries that require large components to be painted to highlight a few. Their utility shines in applications that necessitate extended linear movement, including:

PART TRANSFER

Facilitate the seamless movement of parts between different stages of the production process, increasing throughput and reducing cycle times.

PAINTING

Enable robots to execute consistent, high-quality paint applications over large or complex surfaces, ensuring uniform coverage and finish.

Dispensing

Allow precise control over the linear movement of robots for accurate dispensing of adhesives, sealants, or other materials, enhancing product quality and process reliability.

Machine Tending

Improve efficiency in loading and unloading parts from machines, enabling continuous operation and reducing manual intervention.

MATERIAL HANDLING

Streamline the transport and positioning of materials within the production facility, optimizing workflow and reducing labor costs.