RESOURCES

GUIDE TO WELDING POSITIONERS

About Welding Positioners

Weld positioners can be mounted in any configuration. This enables large weldments, fabrications or assemblies to be rotated in a controlled way in order to present the optimum angle to a welder or operator for welding or other operation such as assembly.

Weld Positioners are used by welders, welding shops and production facilities to position and move weldments in order to:

- increase welding productivity and weld deposition rates

- increase welding quality and reduce errors and rejects

- reduce part movement through the shop

- enable welding specifications to be repeatably met

- reduce welder fatigue

- reduce welding production floor space

- enable robotics to perform welds

- increase safety

- enable large parts to be welded without the welder having to move to access joints

- enable welders of to produce welds through elimination of overhead or vertical welds

Since weld positioners are most often oriented with the axis horizontal, or able to be swung to horizontal, the center of gravity of the part will be overhung from a fixture that holds it. Given enough mass and a long enough part, a tailstock trunnion or set of rollers may need to be added to support the weldment at the other end from the positioner in order to safely support the part. It’s important to note that the center of gravity and lever arm (design torque) can change as parts are welded on to make an assembly so you want to work with an experienced company to make sure that your complete application is taken into account.

Weld positioners may hold the weldment with a special fixture may be made in order to ease mounting and aligning parts and create a safe and reliable welding setup. Chuck tightness or fixtures are set or designed to allow for the thermal expansion that happens as the welding process is performed. The weight of the fixtures has to be taken into account when sizing a welding positioner both for weight and torque from overhang but also from inertia in order to be sure that the system will both perform efficiently and meet the intended design life.

Applications and Options for Weld Positioners

Weld positioners are used in a variety of manufacturing operations, but they are most often used to rotate parts for welding and assembly. Weld positioners are used across industries including aerospace, automotive manufacturing, construction and trains, steel and pipe fabrication, construction, pressure vessel fabrication, machinery manufacturing and more.

Options such as special coatings and custom paint colors, custom central guarding, custom frame widths, continuous, oscillating or flexible modes of operation; custom index times and dwell periods; as well as reinforced cam followers for increased static torque capacities and custom servo brands are available.

Weld positioners are manufactured to perform on a single axis or multiple axis. Single axis weld positioners machines can be provided as a single device for low overhang applications or as a trunnion setup with a headstock and tailstock for longer applications or higher overhang loads. Trunnion weld positioners are usually designed with the tailstock being adjustable to allow for varying length parts.

Multi-axis weld positioners can significantly increase production or enable the fabrication of more complex parts. For instance a dual trunnion system can be mounted on a rotating table, enabling an operator to load one part and rotate it into position for welding while another part is loaded.

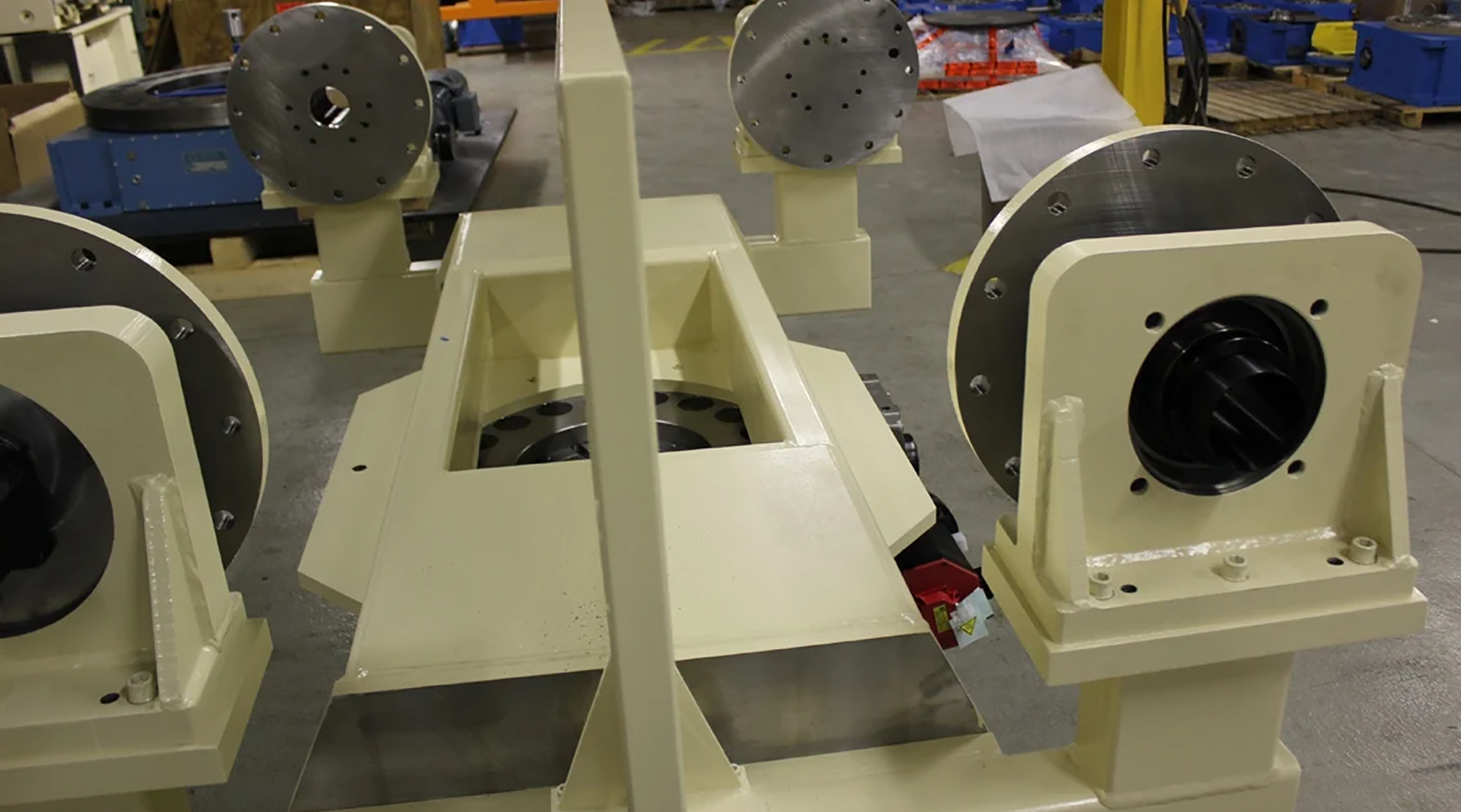

Dual Trunnion Weld Positioner on Rotating Table

Weld Positioner Options will Often Include:

- Special hole patterns in mounting plates on headstock and tailstock

- Clockwise, counter-clockwise and oscillating index modes of operation

- Can be ordered as complete assembly with head stock, tail stock and base frame

- Different gear ratios

- Customer supplied servo motors – Motion Index Drives to mount

- Mechanical homing devices

- Safety locking devices to be used during maintenance and tooling / fixture assembly

- Variety of encoder or positioning devices

- Slip rings

- Rotary unions

Things to Look for in Welding Positioners and Weld Positioner Manufacturers

Of course cost is a factor when selecting any type of automation equipment. Your weld positioner partner should be able to offer extremely high precision, low backlash and zero backlash options at a competitive cost. It’s often advantageous to be able to purchase complete trunnion solutions that might include a heavy duty base frame, riser bases and fixed or custom lengths.

The best headstock tailstock trunnion weld positioner sets utilize a high precision zero back-lash cam operated rotary index table mounted in a vertical position complete with mounting plates. Moving large masses with smaller units maximizes the productivity from your available footprint and also saves cost upfront. Machines should be painted to meet industry standards including specialty paints for corrosive applications if required and completely sealed machine surfaces to eliminate intrusions.

Weld Positioners should have large through holes to run utilities to the tooling and fixtures, easy access to pipe and wire all components and standard models available to quickly initiate the design process.

Weld positioners can have custom controls and pre-programmed panels to create a more flexible automation system and can be paired with robotics to accelerate productivity. You should have a choice of robot manufacturers for your project. Systems integrators that have freedom to choose the robotics manufacturer can adapt to their customers requirements, minimizing design costs from project to project.

Be Sure that Your Weld Positioner Manufacturer:

- Can accommodate all servo motor and robotic motor brands

- Can operate from standard AC motor single or three phase

- Headstock (flexible or fixed index drive, with or without drive motor, servo or AC)

- Tailstock (bearing assembly or thru-hole bearing housing)

- Custom Risers and Center Frames

- Optional controls drive for motor

- Micarta isolation kits for specific welding applications

- Black oxide head and tailstock mounting flanges

The best weld positioner manufacturers offer features that extend machinery life and reduce operating and maintenance costs. Examples are:

- Flame hardened cams

- Multiple oversized cam followers engaged with cam at all times

- Headstock (flexible or fixed index drive, with or without drive motor, servo or AC)

- Programmable rotation angles of both base rotary movement and dual trunnions

- Fixed central guarding between both trunnion sides

- Fully maintainable with all wear components capable of being serviced at facility

- Very low maintenance components

HeadStock TailStock Weld Positioning Systems

Components Features and Options

Standard dual headstock tailstock trunnion positioners utilize a high precision (less than 1 arc second) planetary gear system mounted in a vertical position complete with mounting plates. Headstock Tailstock Trunnion Sets are ideal for moving large masses with smaller units and minimizing your equipment’s footprint on the floor. All trunnion units can be ordered with standard or custom frames fully equipped with head and tailstock supports and one-piece base weldments.

Think a Weld Positioning System will Improve your Manufacturing Capabilities?

Contact us now to speak to an Engineer.