ROBOTIC POSITIONERS

3 AXIS

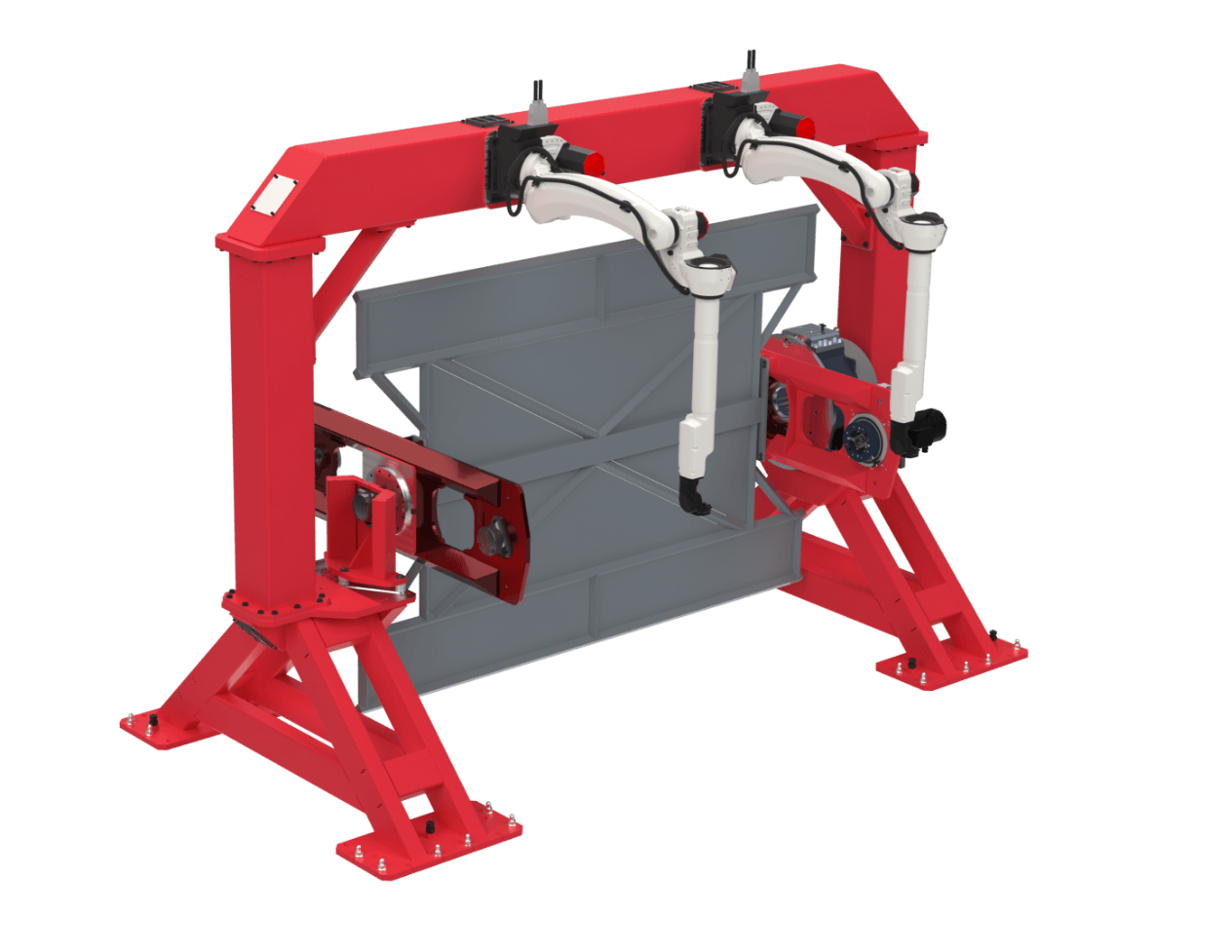

3-AXIS ROBOT POSITIONERS

Three-axis positioning systems represent a cutting-edge solution in the field of automated manufacturing, offering unparalleled precision and efficiency for medium to large complex components. These systems are essential for system integrators and companies aiming to optimize their automated cells, as they enable more dynamic and flexible manufacturing processes. By providing three axes of motion, these positioners can manipulate workpieces in multiple directions, allowing for complex operations to be completed with greater speed and accuracy. This capability significantly shortens work cycles and enhances throughput, making them a valuable asset for any manufacturing operation looking to improve productivity and reduce operational costs.

For mechanical engineers and automation design engineers, the appeal of three-axis positioning systems lies in their ability to integrate seamlessly with robotic automation technology. This synergy allows for the execution of highly precise and consistent welding, cutting, or assembly tasks, as the workpiece can be positioned and repositioned with exactitude. The result is a streamlined production process that minimizes human error and maximizes the quality of the finished product. Moreover, these systems conserve valuable floor space by consolidating multiple functions into a single, compact unit, providing an efficient solution to space constraints in manufacturing facilities.

Investing in a three-axis positioning system is a strategic move for companies seeking to future-proof their manufacturing capabilities. These systems not only facilitate the adoption of advanced automation technologies but also adapt to evolving production needs and industry standards. With their ability to improve product quality, increase production speed, and reduce waste, three-axis positioning systems offer a competitive edge in the market, ensuring that companies remain at the forefront of innovation in automated manufacturing.