ROBOTIC POSITIONERS

2 AXIS

2-AXIS ROBOT POSITIONERS

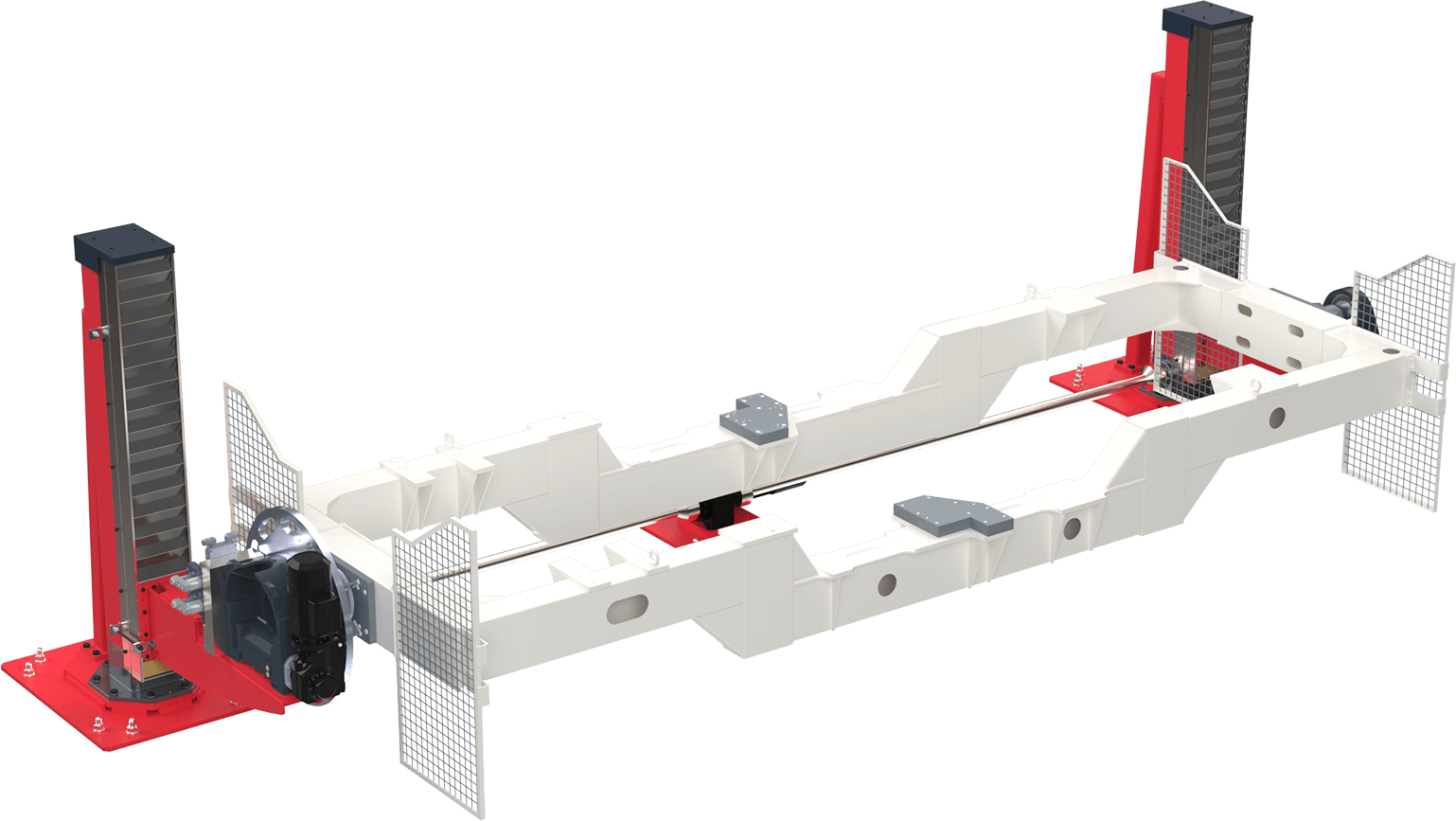

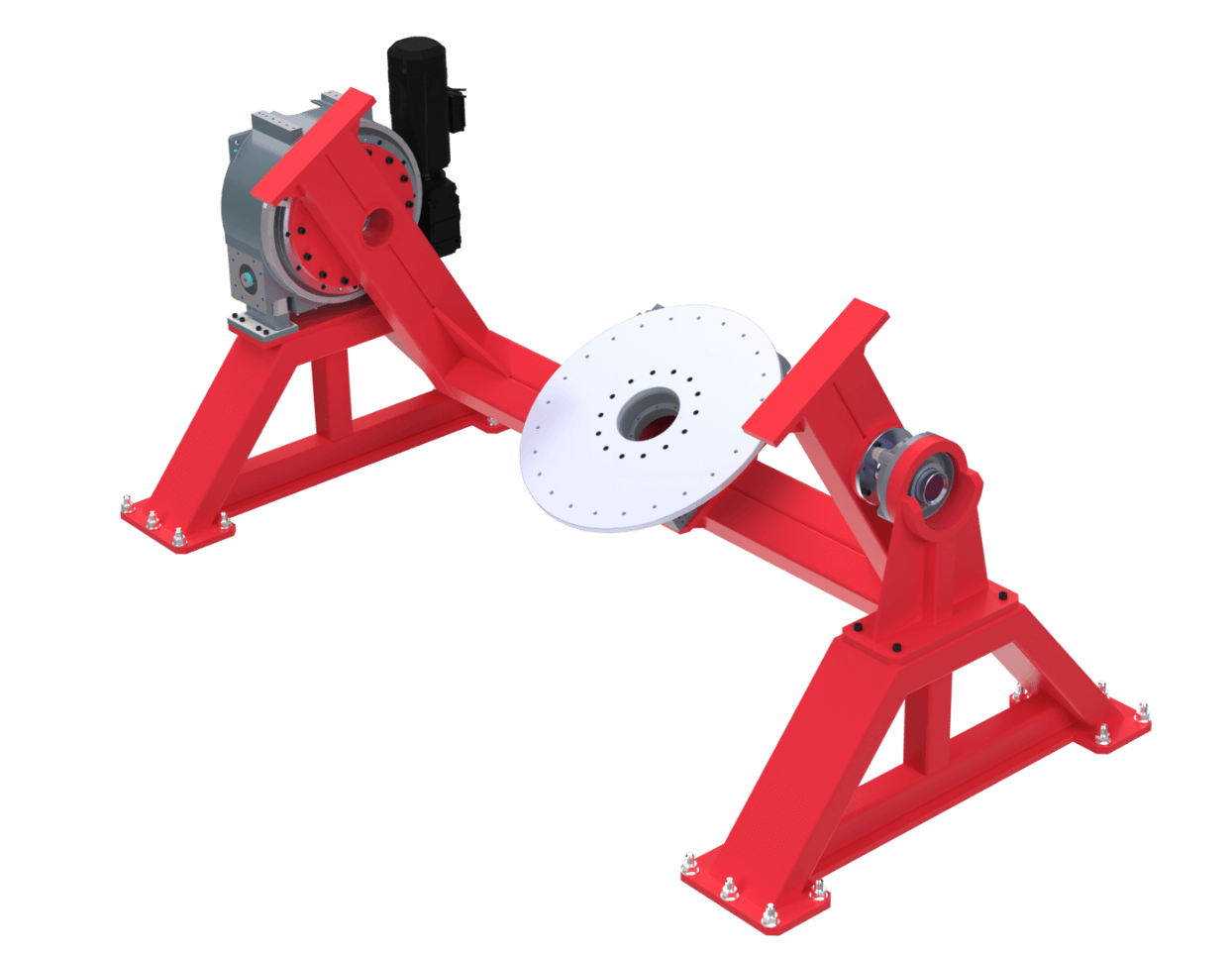

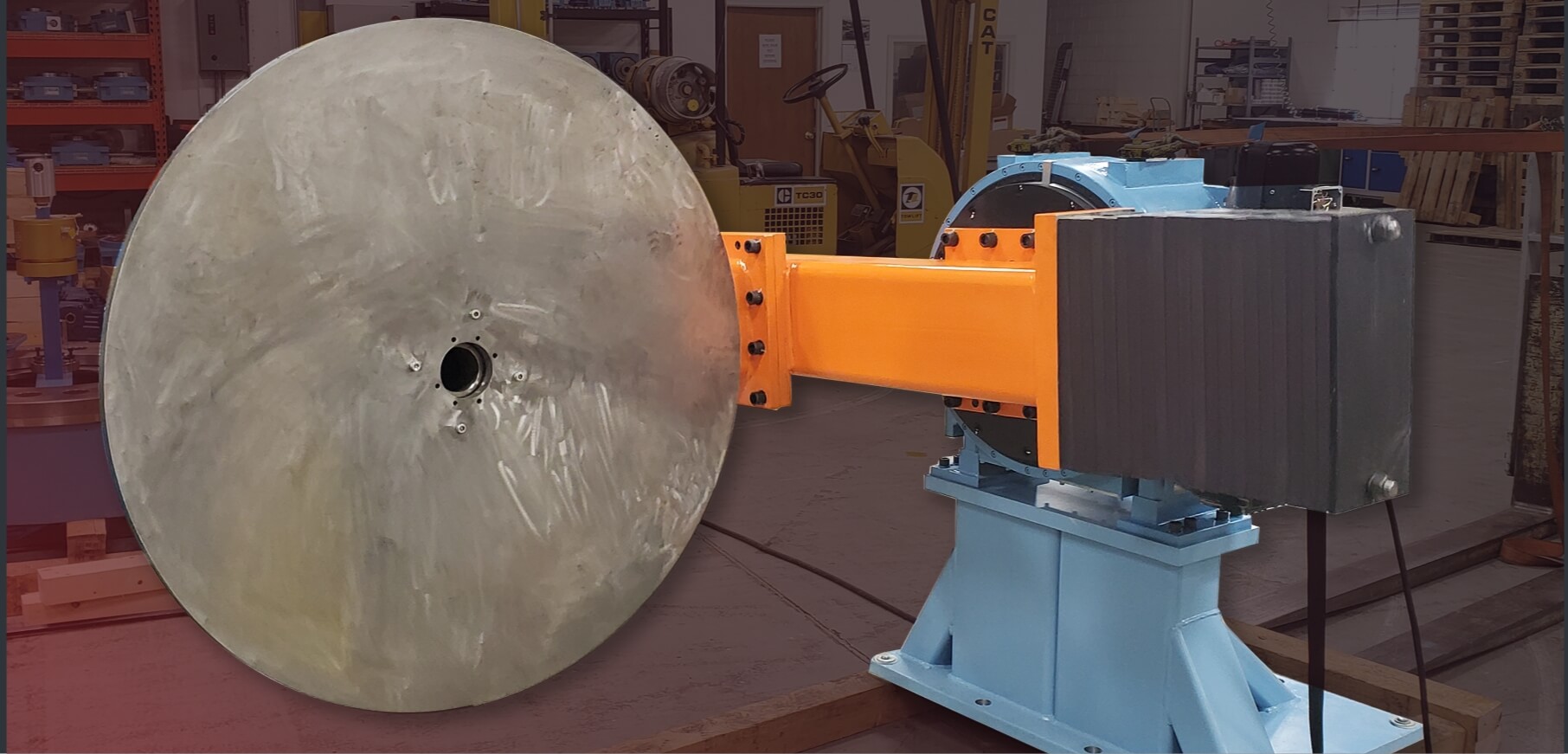

Two-axis robot positioners are innovative tools in the automation sector, providing exceptional precision and agility for handling small to medium-sized components. These positioners are crucial for both system integrators and manufacturers looking to enhance their automation frameworks, as they support more streamlined and adaptable production methods. With two axes of movement, these devices facilitate the orientation and manipulation of parts along two different planes, fostering intricate tasks to be executed with enhanced efficiency and precision. This feature significantly condenses production times and boosts output, establishing them as indispensable assets for manufacturing entities eager to elevate their efficiency and diminish operational expenses.

For mechanical and automation design engineers, two-axis positioners are prized for their seamless integration with robotic systems. This integration fosters the precise and consistent performance of tasks such as welding, cutting, or assembling, as pieces are accurately positioned and adjusted. Consequently, production flows are optimized, reducing manual intervention and elevating the quality of the end products. Additionally, these positioners are space-efficient, merging several functionalities into a unified, compact device, which is a vital advantage for space-limited production environments.

Investing in a two-axis positioning system is a forward-thinking decision for firms aiming to advance their manufacturing processes. These systems not only pave the way for the incorporation of sophisticated automation technologies but also accommodate changing production demands and industry benchmarks. Through their capacity to enhance product quality, escalate production velocity, and minimize waste, two-axis positioning systems deliver a market advantage, ensuring that enterprises stay ahead in the competitive landscape of automated manufacturing.