LAZERARC BLOG

stay in the know with new product updates to see how we can customize your automation process & tips to keep your equipment running smoothly

Enhancing Automation with Robotic Welding Positioners

Enhancing Welding Automation with Robotic Welding Positioners Incorporating single axis trunnions and multi-axis weld positioners into manufacturing operations significantly expands.

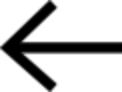

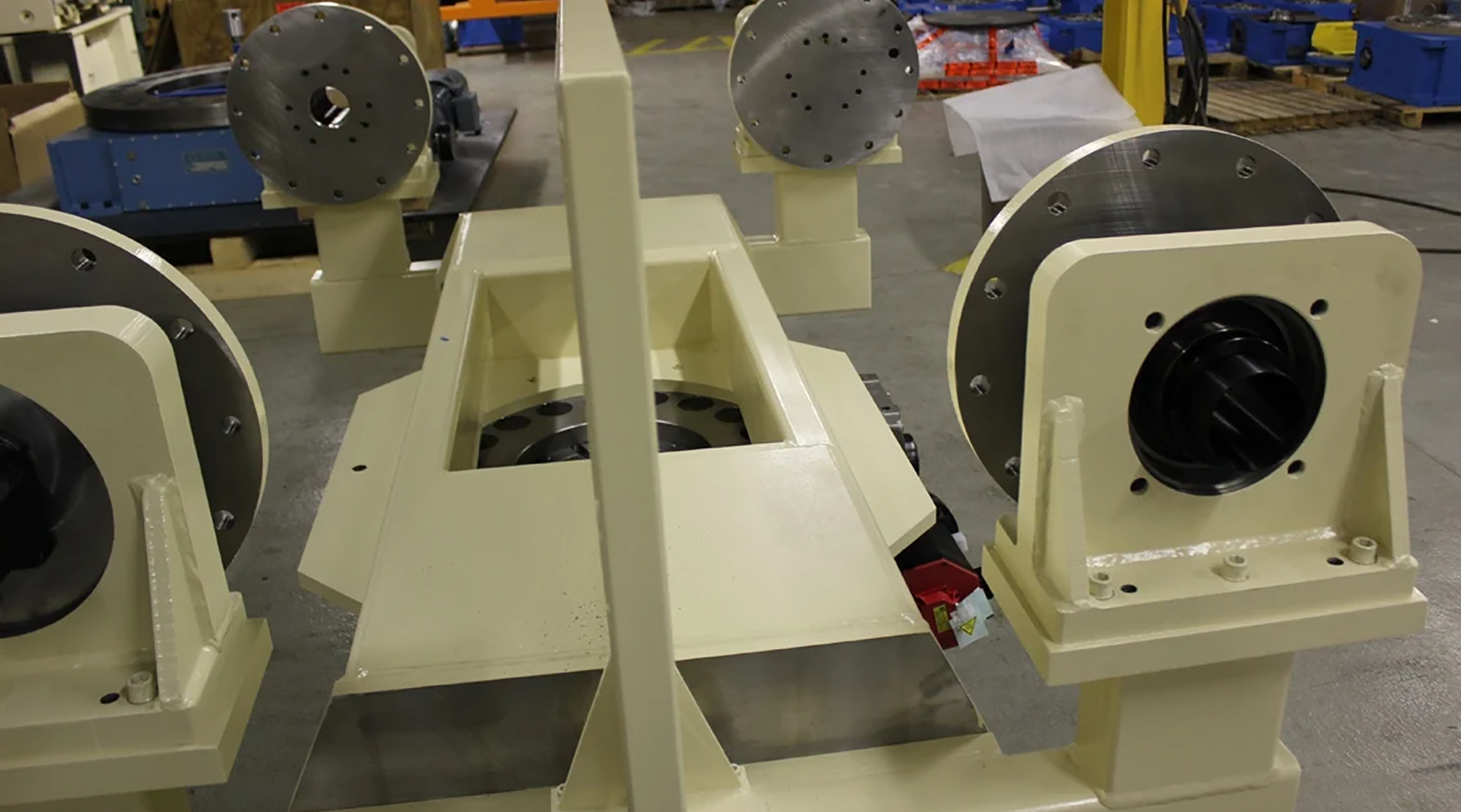

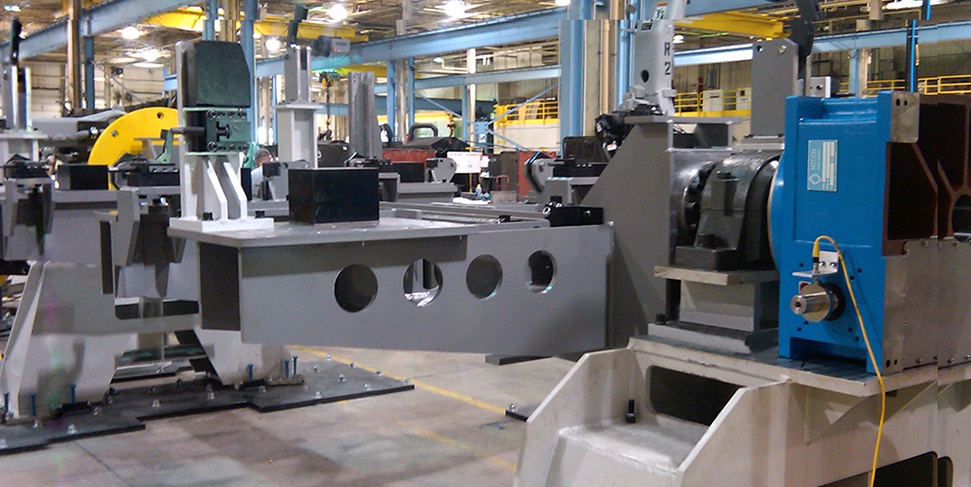

Headstock and Tailstock Sets for Weld Positioning

Overview Headstock and tailstock sets are essential for positioning and assembling long, heavy components, allowing them to rotate for efficient.

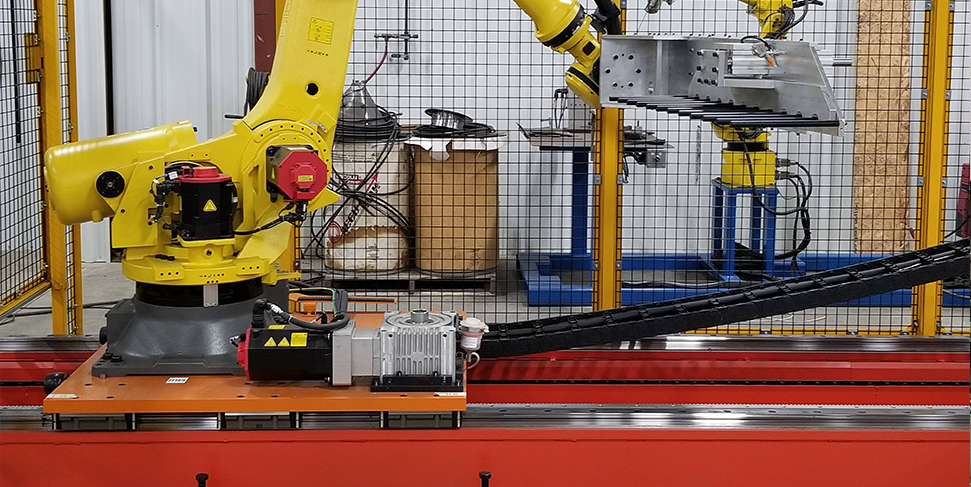

Robot Transfer Units for Material Handling Unit Applications

Robot Transfer Units can significantly extend the usability of 6 Axis Robots by adding a 7th Axis, linear movement of.

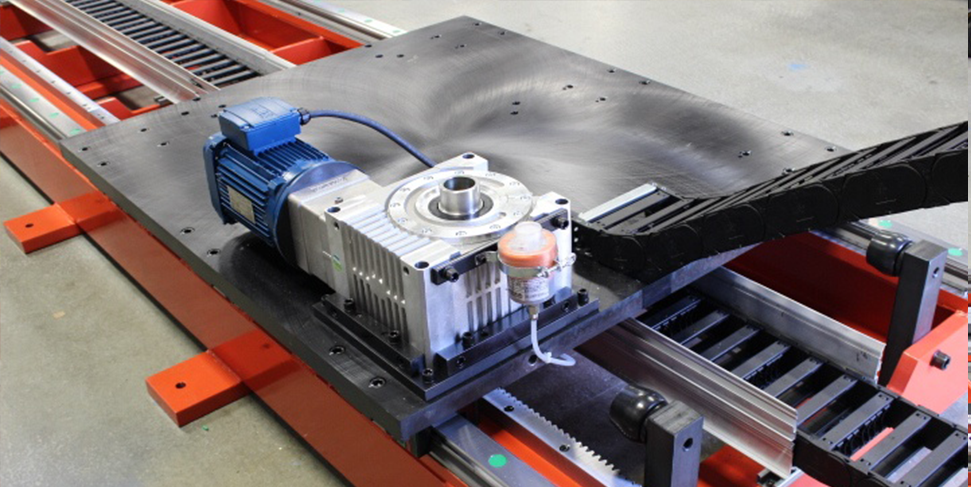

Linear Transfer System Drives

With any mechanical system there needs to be a way to drive the system and Linear Transfer Systems are no.

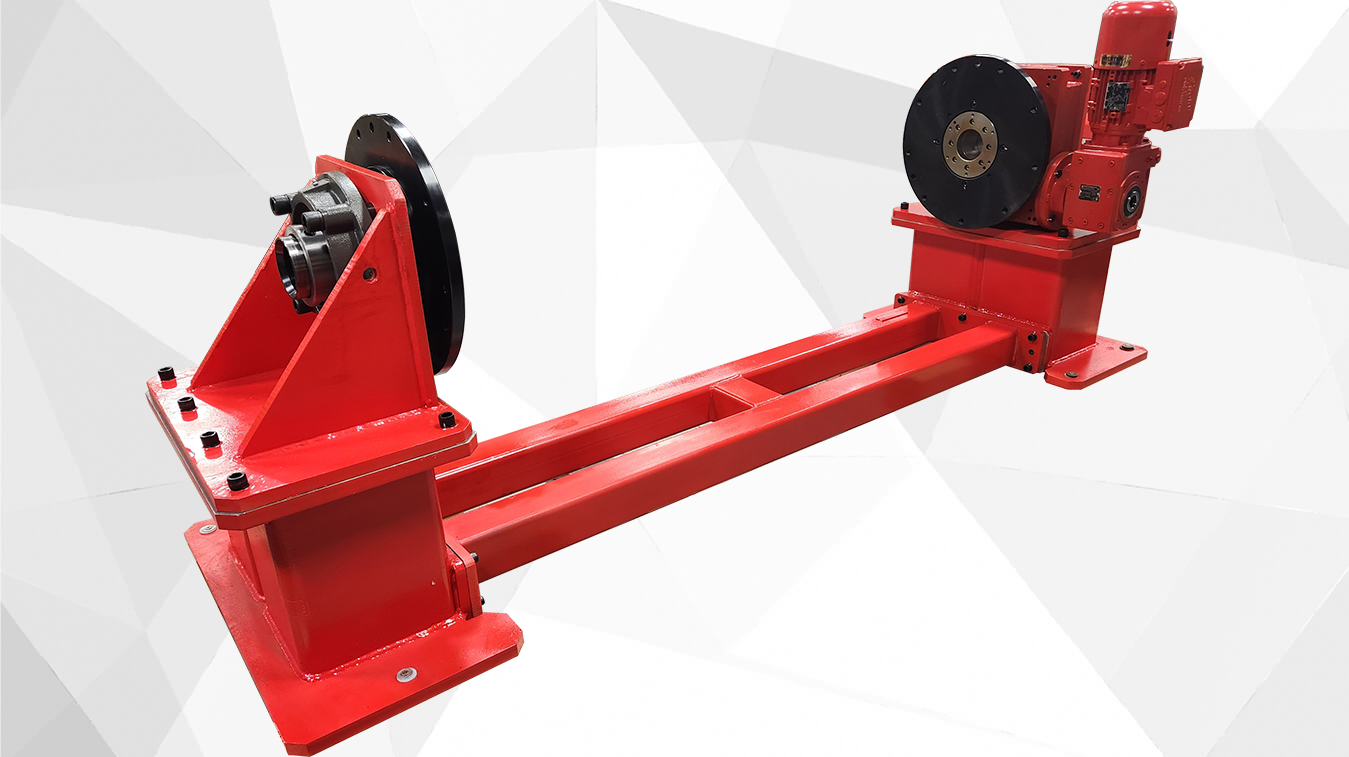

Benefits of Multi-Axis Robotic Positioners

The benefits of Multi-Axis Robotic Positioners by incorporating a central axis that rotates a two-axis system on each side, enhances.

Zero Backlash 5 Axis Robotic Positioning Systems

At the forefront of robotic positioning technology, our 5-axis robotic positioning systems are engineered to deliver unparalleled precision and reliability,.

Linear Transfer Systems Machine Components

A linear transfer system enables diverse function in any production process. As there are a great amount of components attachable.

Manufacturing Applications for Multi-Axis Positioning Systems

Most engineers, designers, and automation integrators are looking for ways to automate production lines, especially for large parts. Manufacturing Applications.

Design Considerations for 7th Axis Robots

Theory of the 7th axis: Design Considerations for 7th Axis Robots applications in production are a key step to improve.

Introduction to Multi-Axis Robotics

Engineers have many choices for robotic or programmable automation solutions. One choice is the number of axis of freedom of.

Why Choose Robotic Part Positioners

Robotic Part Positioners play a pivotal role in granting 360° access to tooling when a robot exceeds it rotational limits..

How to Select Robot Positioners for your Application

Selecting the appropriate robot positioner and components is a pivotal decision for manufacturers seeking enhanced flexibility to elevate weld quality.

INTRODUCTION TO LINEAR TRANSFER SYSTEMS

What are Linear Transfer Units? Linear Transfer Units are a means of transporting items, often robots or components needed for.