industries

DEFENSE

LAZERARC’S INNOVATIVE SOLUTION

LAZERARC’S ADVANCED SOLUTION

TAILORED PRECISION ENGINEERING

FOR THE DEFENSE INDUSTRY

In the demanding and critical realm of the defense industry, precision and customization are crucial. LazerArc rose to the occasion, crafting a bespoke solution specifically for a complex laser descaling project on heavy military vehicles. This project required not only advanced engineering skill but also strict adherence to the detailed requirements for precision and backlash control set forth by the client.

key features

LAZERARC’S CUSTOM DEFENSE INDUSTRY SOLUTION

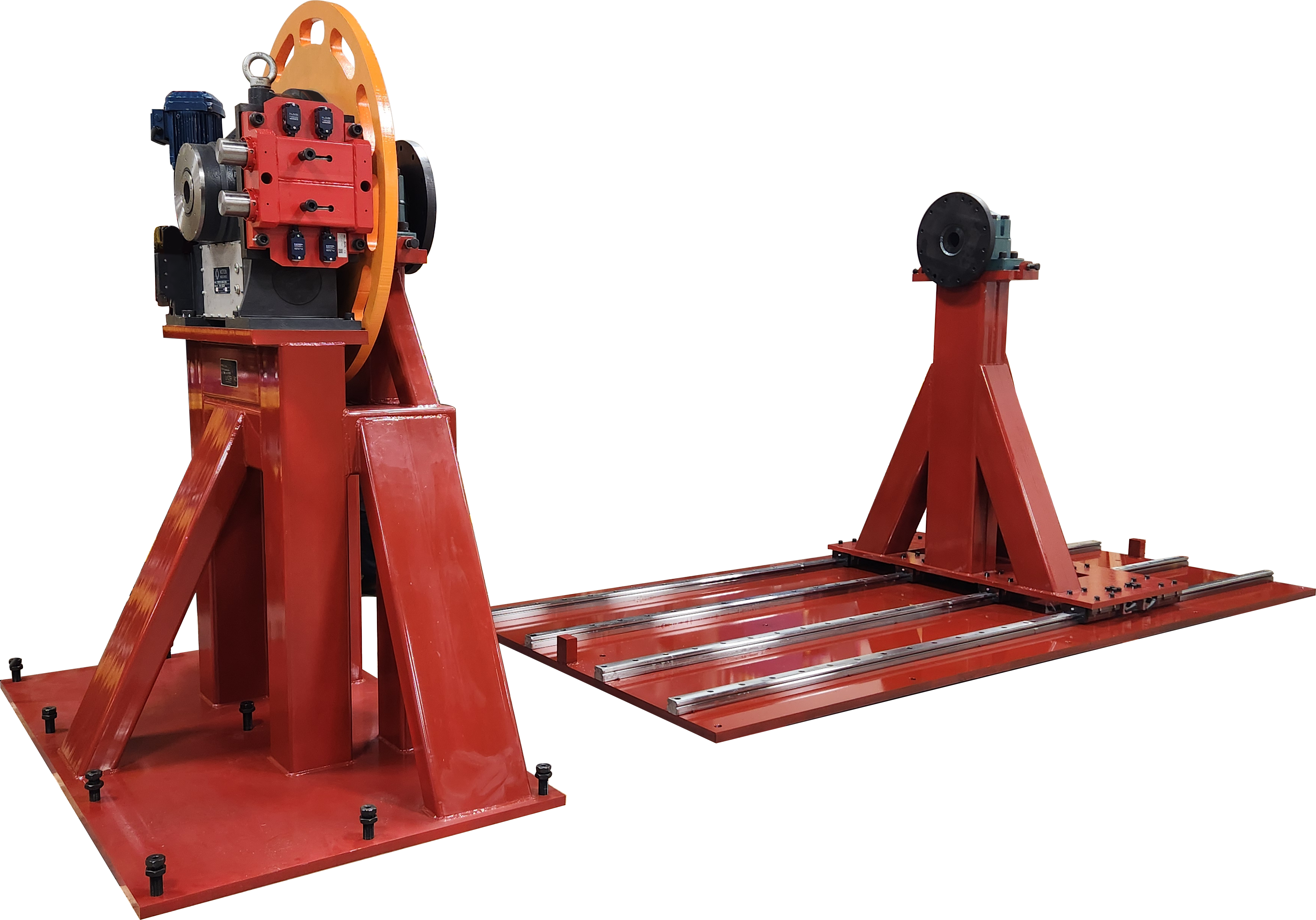

ZERO BACKLASH ROTATION SYSTEM: At the core of LazerArc’s solution was a system designed to eliminate backlash at the output of rotation, essential for the laser descaling process. This feature ensured uninterrupted operation and maintained the integrity of the vehicle surfaces being treated.

ADAPTABLE DESIGN FOR VARIOUS VEHICLE SIZES: LazerArc engineered a system with an oversized linear bearing setup featuring four parallel linear bearings. This design provided the necessary flexibility to accommodate different sizes of military vehicles while maintaining high precision and stability.

VTMF3010 POSITIONING TRUNNION: The robust VTMF3010 trunnion was a key component, known for its strong load-handling capacity and precise positioning. It included an auxiliary axis robot motor for accurate alignment and control, as well as a safety locking mechanism to secure loads even in case of motor brake failure.

ENGINEERED FOR SAFETY AND RELIABILITY: The system was designed with a safety factor exceeding 5:1, ensuring structural integrity and operational safety under the most demanding conditions. Special mechanical locking mechanisms on the linear bearing rails further enhanced stability and prevented unintended movement.

CUSTOMIZATION FOR OPERATIONAL EFFICIENCY: LazerArc’s solution was tailored to meet the exact specifications of the defense application, ensuring that the system could seamlessly integrate into the existing workflow and enhance the efficiency of the laser descaling process.

ROBUST LOAD HANDLING AND PRECISION ALIGNMENT: The integration of the VTMF3010 trunnion and the auxiliary axis robot motor provided a dual-system approach, delivering both robust load handling and precision alignment, critical for the success of the laser descaling operations.

CONCLUSION

LazerArc’s creation of a custom-engineered solution for the defense industry highlights its expertise in delivering specialized, precise, and reliable engineering solutions. By meticulously addressing the unique challenges of zero backlash, adaptability to various vehicle sizes, and robust load handling, LazerArc delivered a system that not only meets but exceeds the demanding requirements of defense industry applications, thereby reinforcing the importance of specialized engineering in maintaining high standards of performance and safety.