industries

AUTOMOTIVE

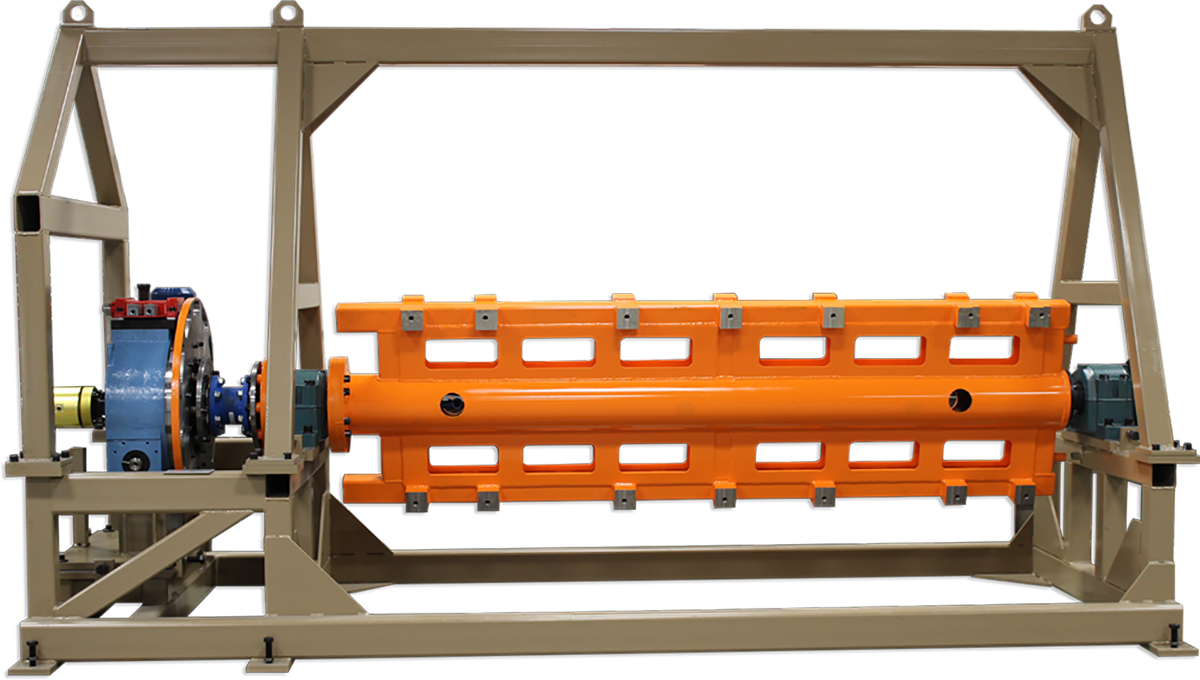

THE VTMF SINGLE AXIS POSITIONING SYSTEM

ENHANCING AUTOMOTIVE MANUFACTURING

In the automotive industry, especially within the Body in White (BIW) sectors, the demand for precision and efficiency in manufacturing processes is paramount. The integration of fully automated weld systems has revolutionized these production lines, but not without its challenges. One of the most critical aspects is the engineering and design of a robust positioning system capable of handling the substantial weight of the tooling and parts involved in welding applications.

A noteworthy solution to this challenge is the implementation of a single axis positioning system, specifically designed using the VTMF series of positioners. This innovative system has been adopted by several global vehicle manufacturers and has proven to be a game-changer in the realm of automotive body side welding applications.

key features

VTMF POSITIONING SYSTEM

HEAVY-DUTY CONSTRUCTION: At the core of the VTMF system is its robust steel fabricated construction, designed to support loads exceeding 40,000 lbs. This sturdy foundation ensures the system can withstand the rigorous demands of automotive manufacturing, providing reliable and consistent performance.

PRECISION POSITIONING WITH VTMF2010 INDEXER: The heart of the positioning system is the VTMF2010 precision trunnion indexer. Renowned for its ability to turn large loads with exceptional accuracy, the VTMF2010 is instrumental in achieving the high precision required in weld applications, thereby enhancing the quality and consistency of the welding process.

ADVANCED UTILITY INTEGRATION: The system’s design includes an electrical slip ring and rotary union, which are pivotal in delivering the necessary utilities to the customer’s fixture or tooling. This integration facilitates seamless operation and reduces the likelihood of system downtime, contributing to the overall efficiency of the manufacturing process.

OPTIMIZED CENTER OF GRAVITY (CG): Collaborative efforts with customers have led to design optimizations aimed at minimizing the CG of the load. By reducing the CG, the system not only achieves better balance and stability but also ensures the longevity and durability of the positioner, thereby safeguarding the investment in the manufacturing setup.

FLEXIBILITY AND ALIGNMENT: The inclusion of a heavy-duty flexible coupling system addresses potential misalignments, accommodating slight discrepancies without compromising the system’s performance. This flexibility is crucial in maintaining the operational integrity of the positioner under varying load conditions and during extensive use.

CONCLUSION

The VTMF single axis positioning system represents a significant advancement in the automation of automotive body side welding applications. With its combination of robust construction, precision engineering, and thoughtful design considerations, it offers a reliable and efficient solution to the challenges faced in the Body in White areas of vehicle manufacturing. The successful implementation of this system across various global manufacturers underscores its effectiveness and the value it brings to the automotive industry.