case study

CUSTOM ROBOT TRANSFER UNIT

CUSTOMIZED IT TO FIT YOUR APPLICATION

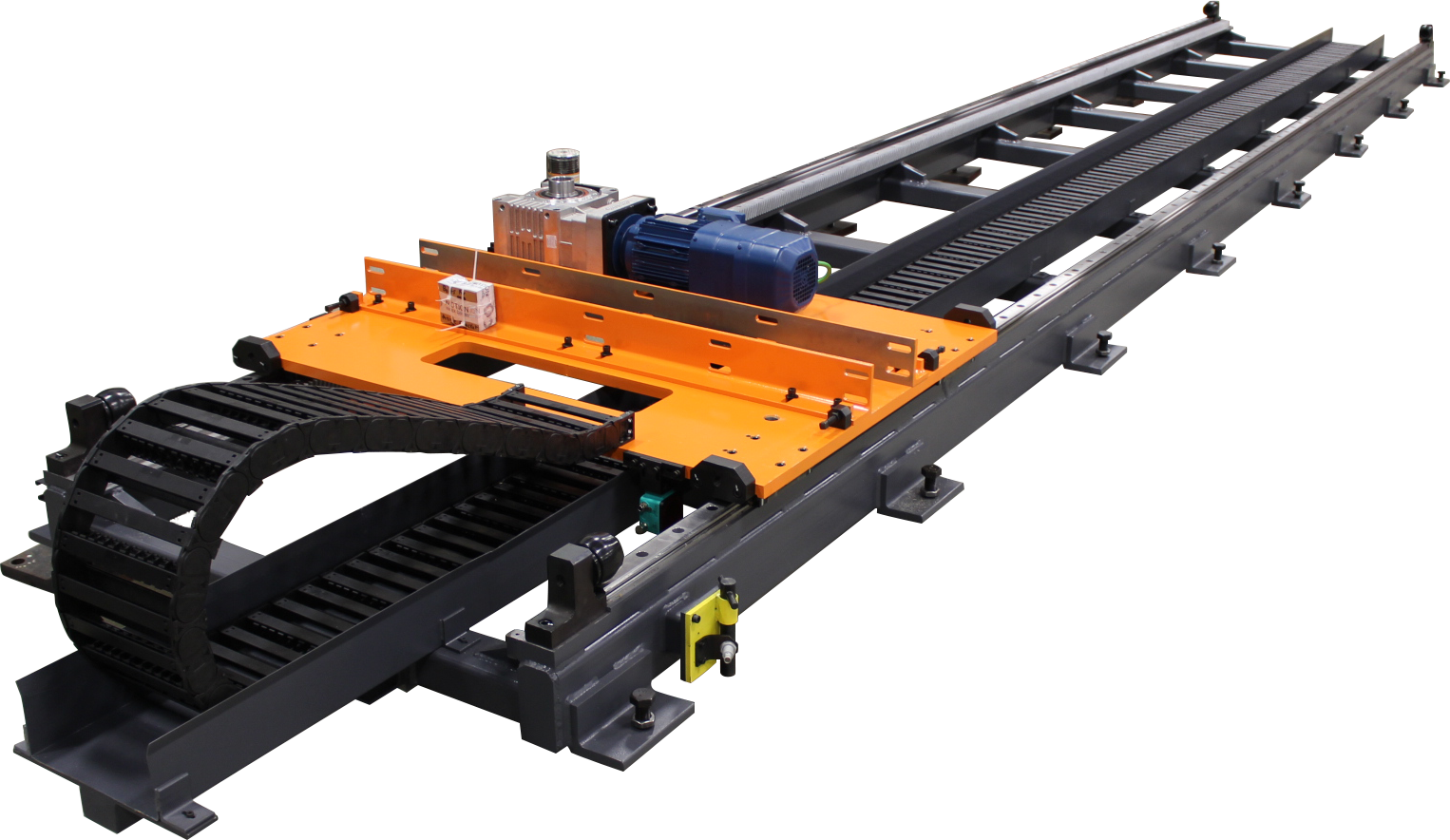

LazerArc was commissioned to develop and fabricate a linear transfer shuttle, blending features of both a robot transfer unit and a tool tray transfer unit. The project came with specific criteria relating to payload capacity, speed, overall size, and crucially, maximum height.

The most challenging design parameters included the need to transport nearly 2.5 tons across a 5-meter span in approximately 10 seconds, all while maintaining a maximum height of 314mm from the floor, accounting for leveling requirements. To meet these demands, a tubular steel structure was meticulously crafted using thick-walled steel tubing to ensure rigidity. The leveling feet were strategically positioned on the same plane as the bottom tube structure to achieve a lower profile, while a precisely machined carriage plate facilitated this reduced height.

Heavy-duty variants of 45 series linear bearings were employed to manage the hefty load, complemented by a high-torque, extremely low backlash reducer (less than 1 arc-min) for smooth and precise movement.

In terms of precision, the objective was to achieve positional accuracy within +/-0.25mm in all directions. A rack and pinion system was selected for its 100% repeatability and an accuracy of +/-0.1mm. However, to ensure absolute confidence in positioning, an additional linear encoder system was integrated, providing a feedback accuracy of +/-0.1mm. This redundancy is particularly valuable, as it guarantees positional awareness even in scenarios where the motor may be altered or removed, maintaining constant knowledge of linear position.