Why choose a robotic welding positioner?

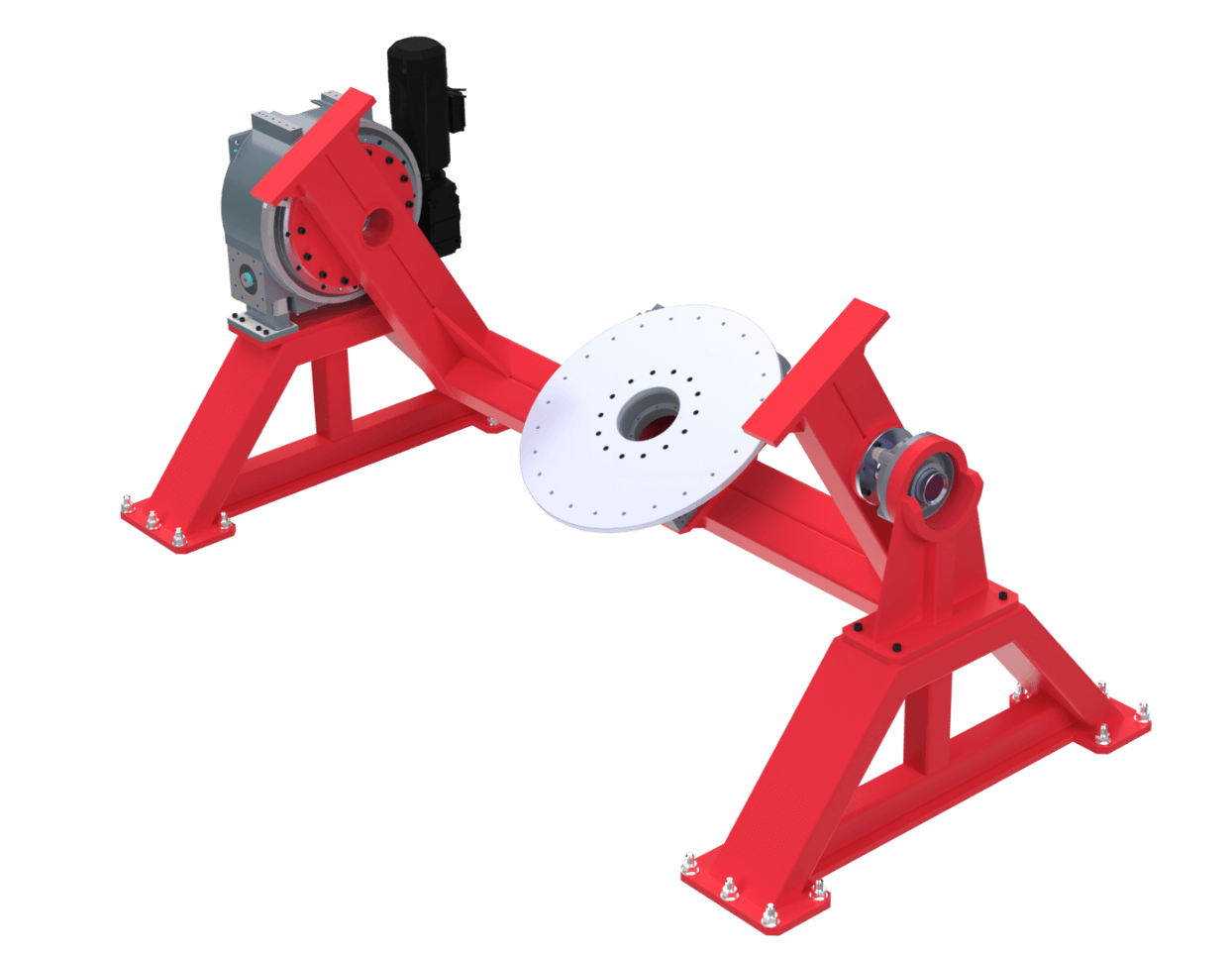

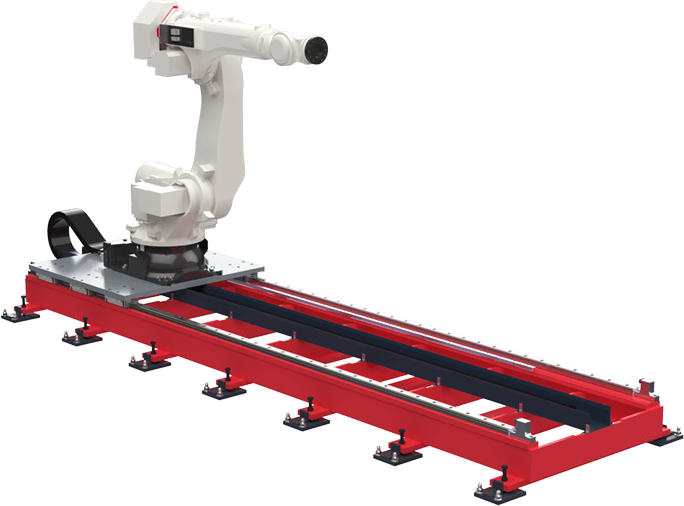

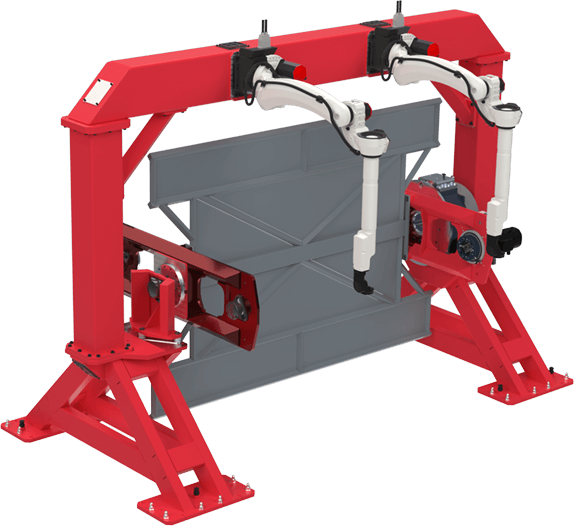

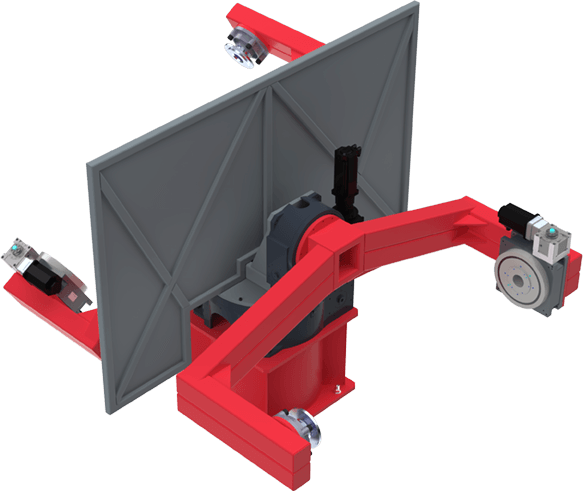

Robotic Part Positioners play a pivotal role in granting 360° access to tooling when a robot exceeds its rotational limits. By managing the rotation of parts, these positioners enable the robot to achieve complete access to workpieces situated beyond its inherent range of motion.